We are your rubber solutions partner for the rail industry

At Cokers we supply parts manufactured from High Performance Low Smoke, Low Toxicity Elastomers designed for the Rail Industry to meet EN 45545 Part II (Fire Protection of Railway Vehicles).

Our extensive range of rubber and silicone elastomers are suitable for all applications from trackside, surface, sub-surface, tunnel, rolling stock and passenger safety applications.

Materials used include Non Conductive Neoprene, Non Conductive Hypalon, Non Conductive Vamac and speciality silicone grade FR8700U from Elkem Silicone Products.

FR8700U is suitable for the production of profiles (doors, windows, walls), panels used in rolling stock and any flexible moulded items which need to combine high fire performance with low smoke emission.

With our in-house tool room we offer a full tool making service, including provision of proto-type tooling if required. This means we can fully manage your project in-house and provide you with a speed of turnaround as well as a high quality product.

Products include:

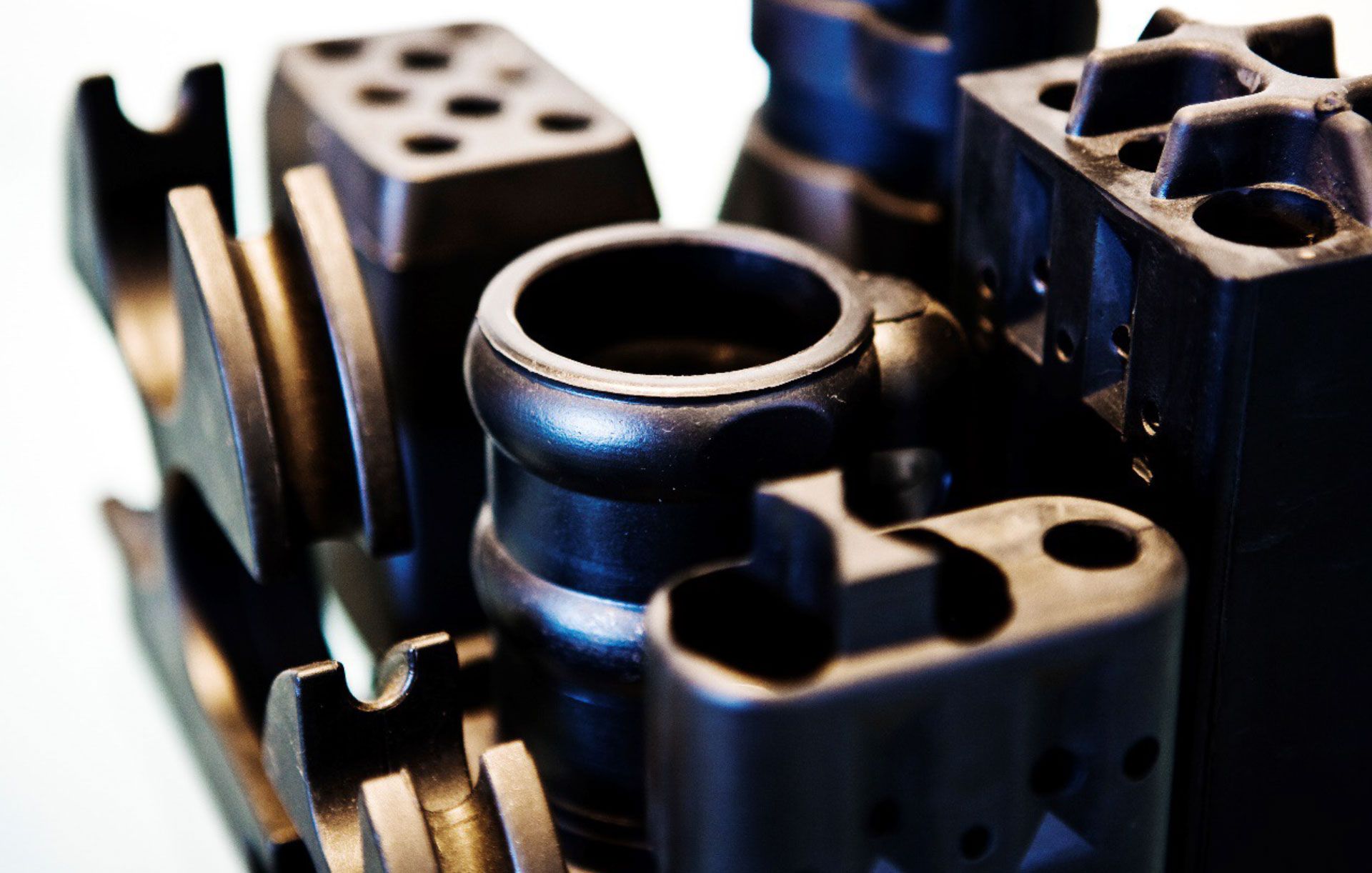

- Bespoke moulded components;

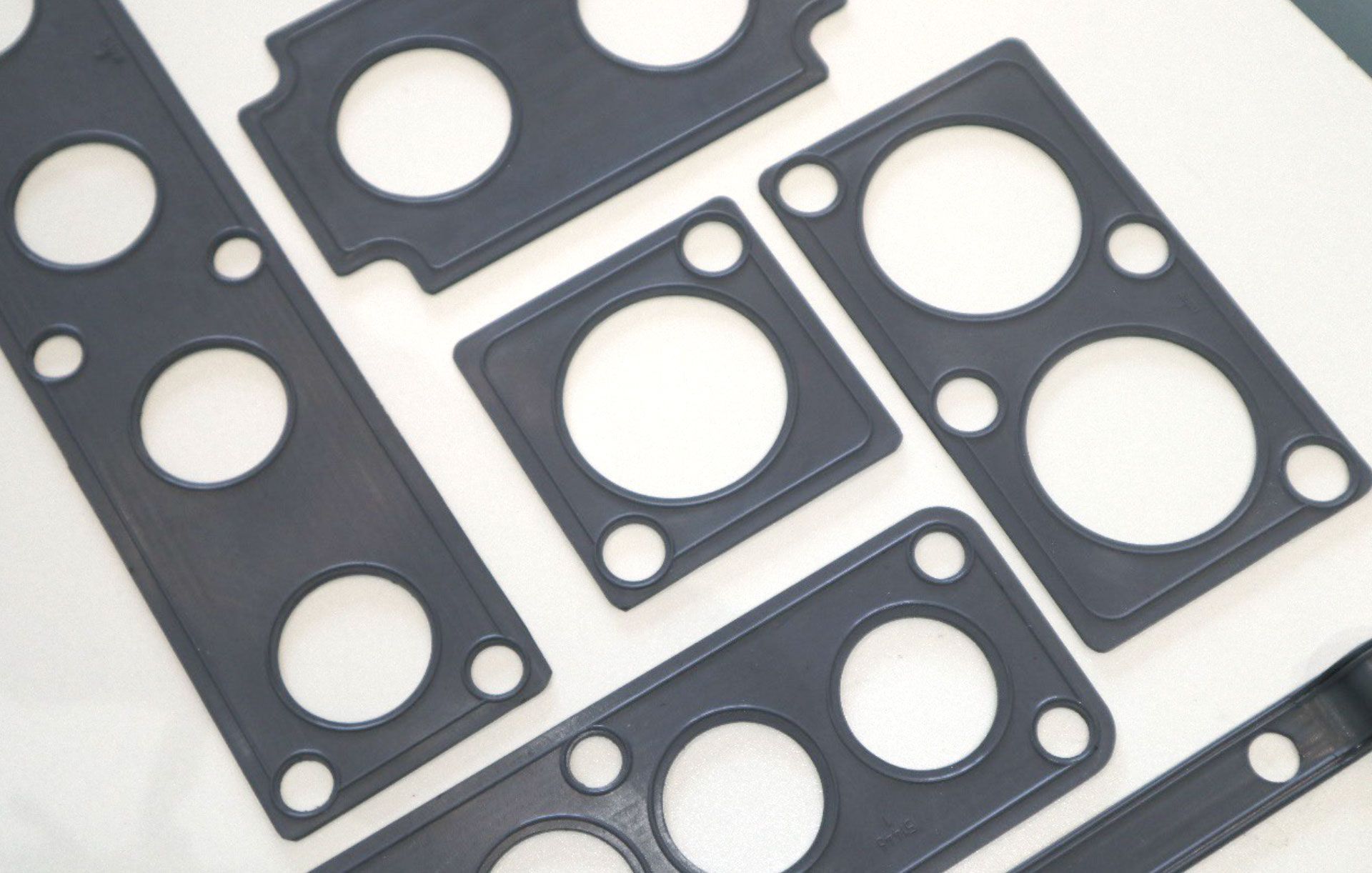

- Cut gaskets;

- Extruded profiles and sections;

- Vulcanised window and door seals.

We are proud of our ISO 9001:2015 accreditation by The British Assessment Bureau and will provide you with the reassurance of full traceability and certificate of conformity as standard.

Hours

8-5pm

Mon - Fri

(open until 1pm on Friday)

Service area

Worldwide

Contact our rail specialist

01795 535008

info@j-coker.co.uk

RAIL: CASE STUDY

"J Coker Ltd have been a key Tier 1 supplier to LPA for a number of decades now. Their quality, service and experience have ensured our success with a number of major UK Rail projects over the past couple of years.

They remain our first choice supplier for all our rubber moulded components for our aviation and rail product ranges. I would highly recommend J Coker Ltd."

Neil Sharpe, Purchasing Manager, LPA Connection Systems.

LPA Connection Systems design and manufacture flexible product solutions for complex electrical inter-connection applications. Their products include:

- Inter-car connection systems for rail rolling stock;

- Ground power supply aviation products including connectors and cable carriers;

- Niphan range of industrial connectors for rugged environments.

LPA Connection systems is ISO 9001 certified and is approved by companies such as Bombardier Transportation, Hitachi Rail, Crossrail, London Underground, London Heathrow and Gatwick Airports.

Our methods

Tool making

The first stage in the design and development process. J Coker’s on-site tool room is headed up by Andrew Coker, a highly experienced tool maker.

Fabrication

Fabrication services covers a multitude of products, particularly those too large to be moulded. From hand-made bellows and sleeves and rubber lined pipes to cut gaskets, washers and rubber sheeting.

Casting discs

We manufacture our own range of rubber and silicone casting discs for centrifugal casting.

We highly recommend J Coker Ltd

Neil Sharpe, Purchasing Manager, LPA Connection Systems

Cokers really helped us out with our projects. Speaking to their design team allowed us to more closely understand the processes they use, which meant we could adjust our design to reduce tool making time and improve productivity. We have been very impressed.

Joe Gibbons, CAD Engineer, DJH Engineering.

We've been using Coker for two decades now and both the products and service have always been fantastic. The staff are friendly and help is always available for any technical queries you might have.