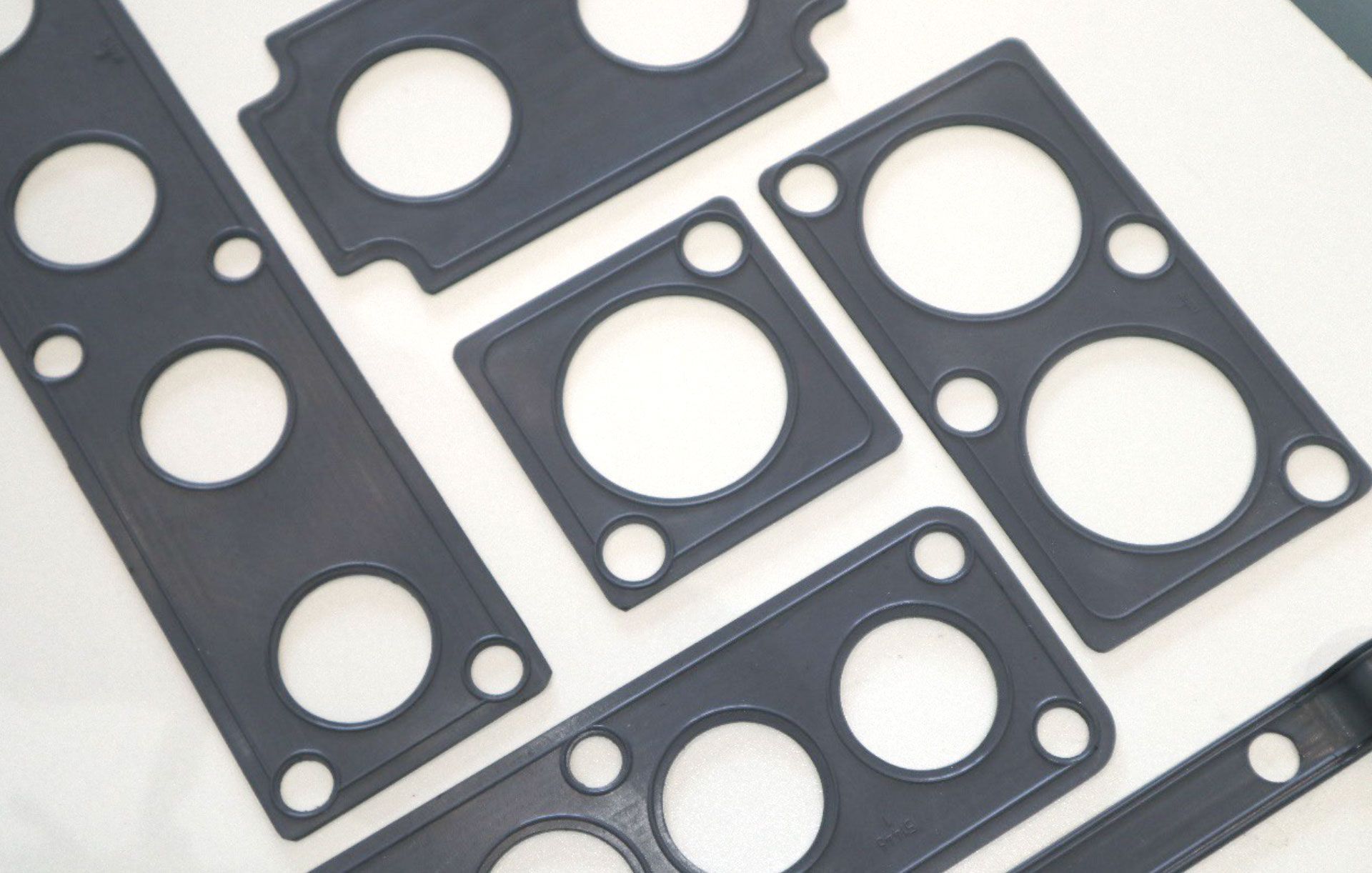

We are your rubber solutions partner for manufacturing

Bespoke mouldings, gaskets, washers or extrusions, the manufacturing sector has a wide variety of needs. We supply products to all aspects of manufacturing from: machinery and tool manufacturers, food and beverage processors, cosmetics industry; engineering to defence and scientific sectors.

As designers of new products, this sector can take advantage of our tool making facilities for new products, and particularly, our ability to supply prototype tooling. This provides a cost effective solution to prove products before full production tooling is laid down.

Hours

8-5pm

Mon - Fri

(open until 1pm on Friday)

Service area

Worldwide

Contact our manufacturing specialist

01795 535008

info@j-coker.co.uk

CASE STUDY – PHARMACUTICAL

"Roland has been making the drill bits and other specialised manufacturing tooling for our manufacturing sites for a number of years and we are very happy with the level of quality and service provided. I would recommend Cokers as a supplier for specialised bespoke tooling."

Dave Hounsell

Principal Engineer, Advanced Manufacturing & Sustaining Engineering

Founded in 1984, ICU Medical are an innovative, clinician-founded company, that have established themselves as a global leader in IV therapy. IV therapy is one of the most common invasive hospital procedures worldwide, with over 80% of patients receiving IV therapy during their stay in hospital.

Working with Dave Hounsell, Principal Engineer Advanced Manufacturing and Sustaining Engineering, Cokers have completed a number of highly specialised tool making projects for their sites in Ashford, Kent and Hranice, CZECH Republic.

One such project is the manufacture of replacement Epidural Eye Drill Bits.

Roland, Coker’s Design Engineer, uses ICU Medical’s PDF files to form the drill bits to a very exact tolerance (+/- 0.01). The drill bits are to be used in epidural cannulas and therefore precision manufacturing is a must.

The drill bits are manufactured out of silver steel which is hardened and cylindrically ground to ICU Medicals design requirement. The parts are then acid etched to a very fine tolerance to form the bespoke profile.

In order to check and approve the parts, Roland then scientifically measures each drill bit with our high precision shadow graph to ensure 100% accuracy.

Our methods

Tool moulding

The first stage in the design and development process. J Coker’s on-site tool room is headed up by Andrew Coker, a highly experienced tool maker.

Fabrication

Fabrication services covers a multitude of products, particularly those too large to be moulded. From hand-made bellows and sleeves and rubber lined pipes to cut gaskets, washers and rubber sheeting.

Casting discs

We manufacture our own range of rubber and silicone casting discs for centrifugal casting.

We are happy to recommend J Coker Ltd for all our tool making services.

Russell Mewett, Director, Mewett Polyurethane

Cokers really helped us out with our projects. Speaking to their design team allowed us to more closely understand the processes they use, which meant we could adjust our design to reduce tool making time and improve productivity. We have been very impressed.

Joe Gibbons, CAD Engineer, DJH Engineering.

We've been using Coker for two decades now and both the products and service have always been fantastic. The staff are friendly and help is always available for any technical queries you might have.