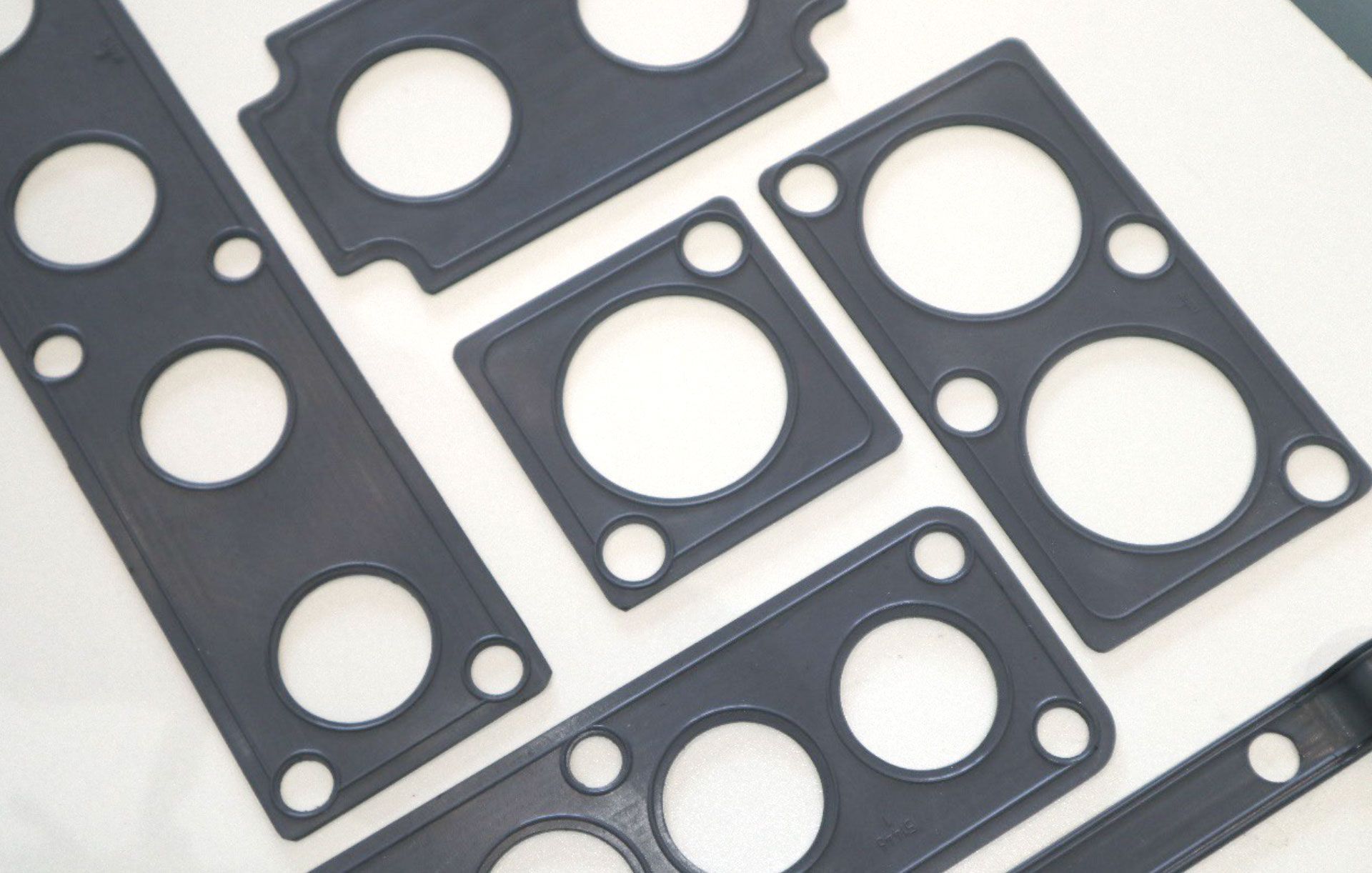

Organic & Silicone Discs – All Grades & Sizes

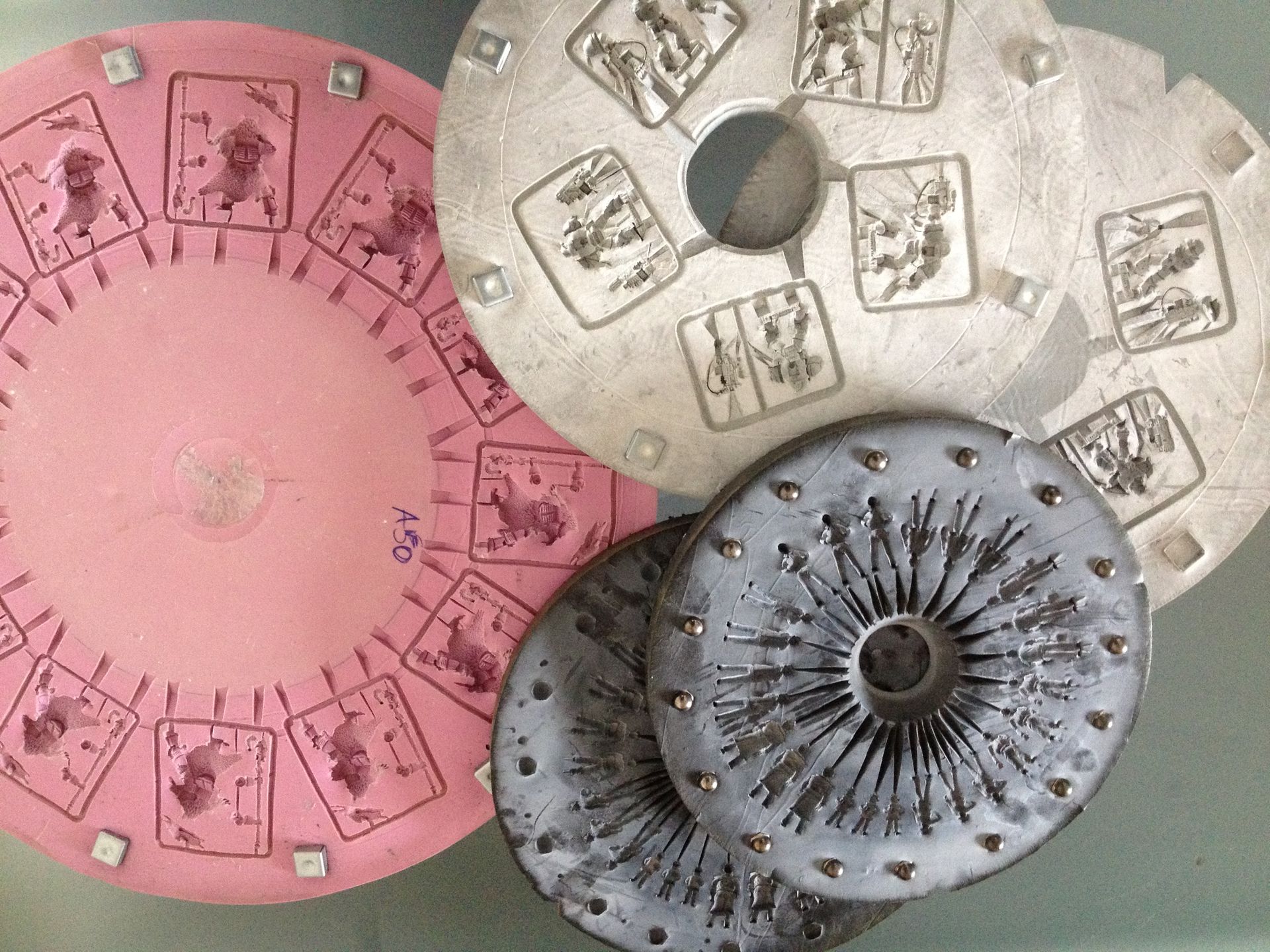

We manufacture our own range of rubber and silicone casting discs for centrifugal casting.

Used by the giftware and model craft industries, our casting discs withstand the heat and pressure required for white metal casting in the manufacture of figurines, pewterware and other gifts.

High heat silicone formulations developed to withstand higher pouring temperatures of zinc and resin.

Hours

8-5pm

Mon - Fri

(open until 1pm on Friday)

Service area

Worldwide

Contact our disc specialist

01795 535008

info@j-coker.co.uk

Traditional Black

Organic Discs

- Range Of Formulations To Suit

- Various Shore A Hardnesses To Suit

- Easy To Peel Laminations

- Good Flow Rubber

- Minimal Distortion

Silicone Discs

- Offer increased production through

longer life - Easy to produce moulds with putty like consistency

- Greater spin life expectancy

- Strong and durable

- Available in low temperature, general purpose and high heat formulations

Full Range of Casting Accessories

- Location studs

- Dusting Chalk

- Swann Morton Craft blades and handles

- Silicone Release agent & cleaning solvents

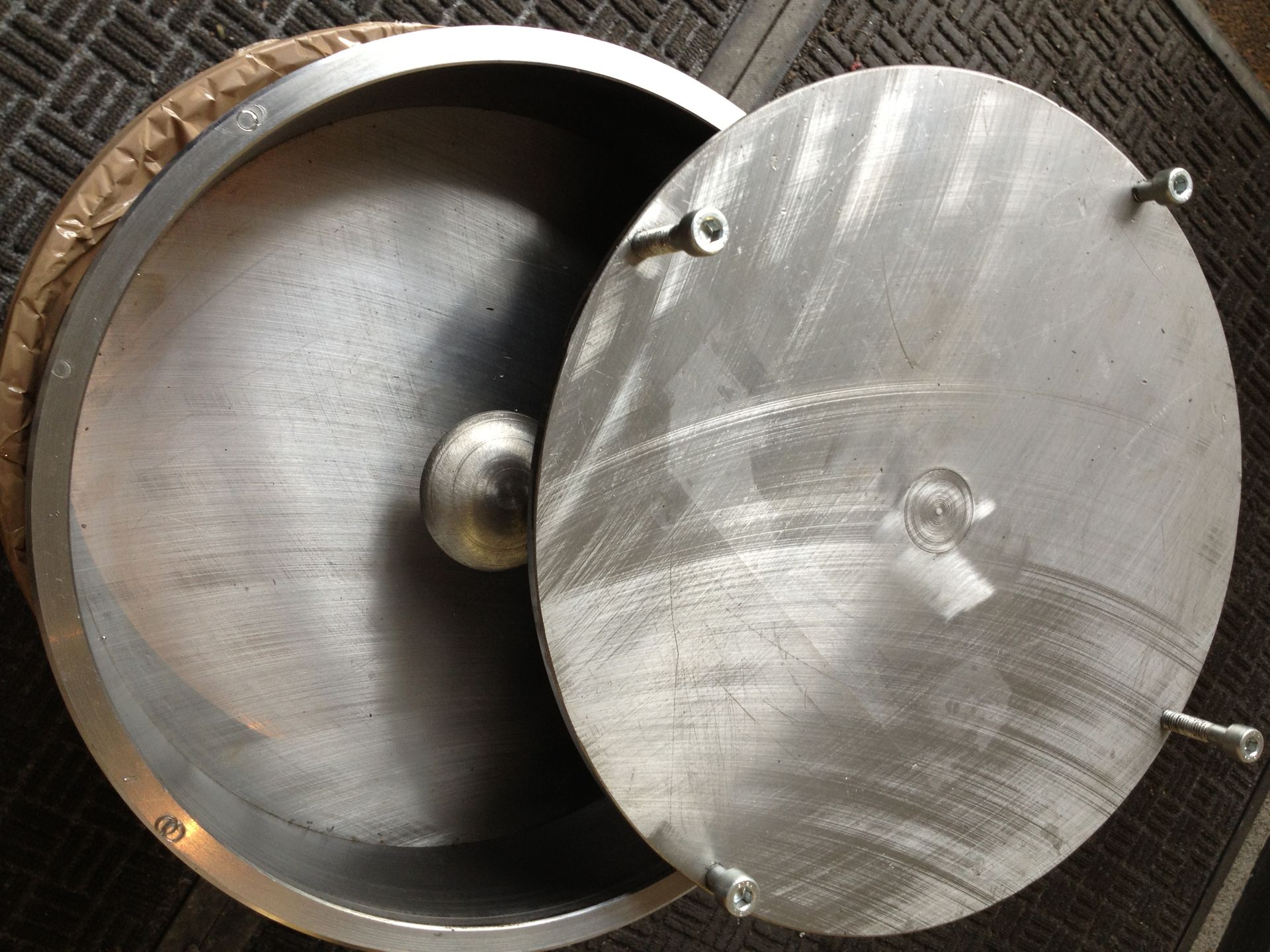

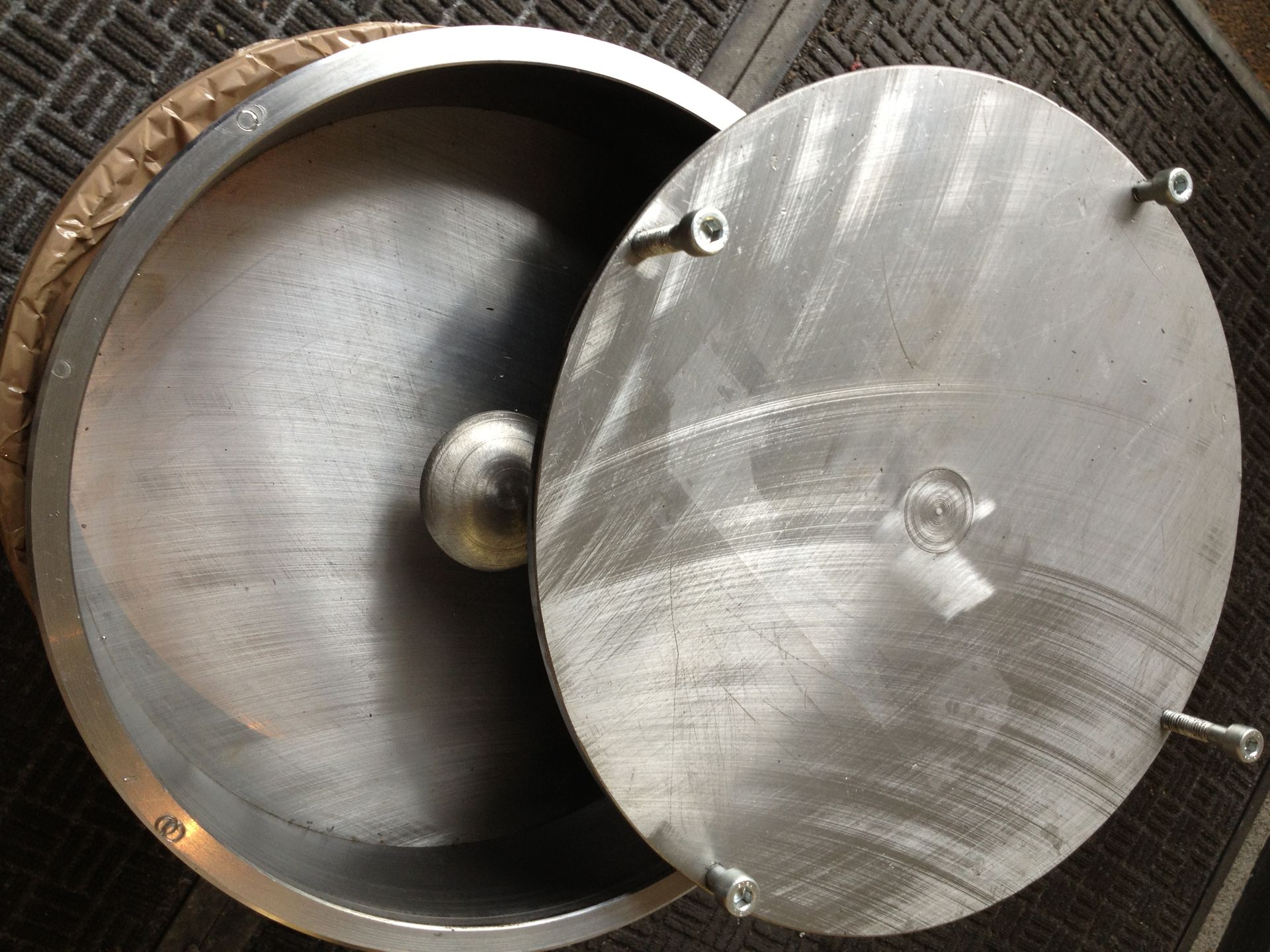

- Made to measure mould cans

Multiple grades

J100. Good all round organic disc for detail and undercuts. 60 IRHD

Grade 50. Soft and highly pliable organic disc. 50 IRHD.

Grade 60 Average hardness organic disc with good shrinkage, 60 IRHD

Grade 70 Strong organic disc with high heat resistance. 70 IRHD

LOW TEMP SILICONE Available in CREAM (70 IRHD) and GREY (60 IRHD). All the benefits of easy mould making plus low cure temperature of 90 degC

GENERAL PURPOSE SILICONE All the benefits of silicone mould making at cure temperature to match organic rubber

HIGH HEAT SILICONE All the benefits of Low Temperature cure silicone but formulated to spin with higher heat metal and resin.

MODEL MAKING: CASE STUDY

For over 40 years, DJH Engineering have built a reputation of excellence in the design and manufacture of bespoke projects such as scale models, corporate gifts, collectables and awards.

As a pewter foundry, DJH are specialists in casting from pewter - a high quality, precious metal known for its unique properties including exceptional corrosion resistance and durability. In addition to pewter, they are also able to incorporate a wide range of other materials as requirement by the project – including rubber, plastic, nylon, brass and steel.

www.djhengineering.co.uk

MODEL MAKING: CASE STUDY

JCB and Titan Scale Construction Models

DJH were tasked with manufacturing scale models of the 1980 JCB 3CX Sitemaster and the Terex Titan Dump Truck. Each unique design needed to replicate their full-scale counterpart down to the finest detail.

DJH were tasked with manufacturing scale models of the 1980 JCB 3CX Sitemaster and the Terex Titan Dump Truck. Each unique design needed to replicate their full-scale counterpart down to the finest detail.

J Coker Ltd had supplied DJH with centrifugal silicone casting discs for over 20 years. Knowing that Cokers were also tool makers and rubber moulders, DJH Engineering approached them to help with the production of replica rubber tyres for both projects.

DJH were able to provide excellent in-house drawings of each of the three tyres needed. Each tyre was detailed with replica tread, tyre pressure information and logos.

Coker’s converted the files into a CAD file format, setting the designs into tooling blocks for cutting on our HAAS tool room mills. Each file is re-sized to take into account the shrinkage in rubber when it is moulded.

The detail of the treads was replicated by spark eroding. This process requires a copper electrode to be cut. The electrode is then used to gently spark the profile into the steel tool where ordinary milling cutters cannot reach.

The fully assembled tools are then set up in any of Cokers range of Panstone automatic moulding presses. Moulding temperatures, cure times, pressure and materials are trialled to mould the perfect tyre.

“Cokers really helped us out with these projects. Speaking to their design team allowed us to more closely understand the processes they use, which meant we could adjust our design to reduce tool making time and improve productivity.

We have been very impressed with the tyres. Our client says the tyres really help lift the Terex Titan model above other models. We’re looking forward to the release of our 1980 JCB 3CX Sitemaster this year, the soft tyres really create some realism thanks to the weight of our brass and pewter model.”

Our methods

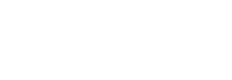

Tool moulding

The first stage in the design and development process. J Coker’s on-site tool room is headed up by Andrew Coker, a highly experienced tool maker.

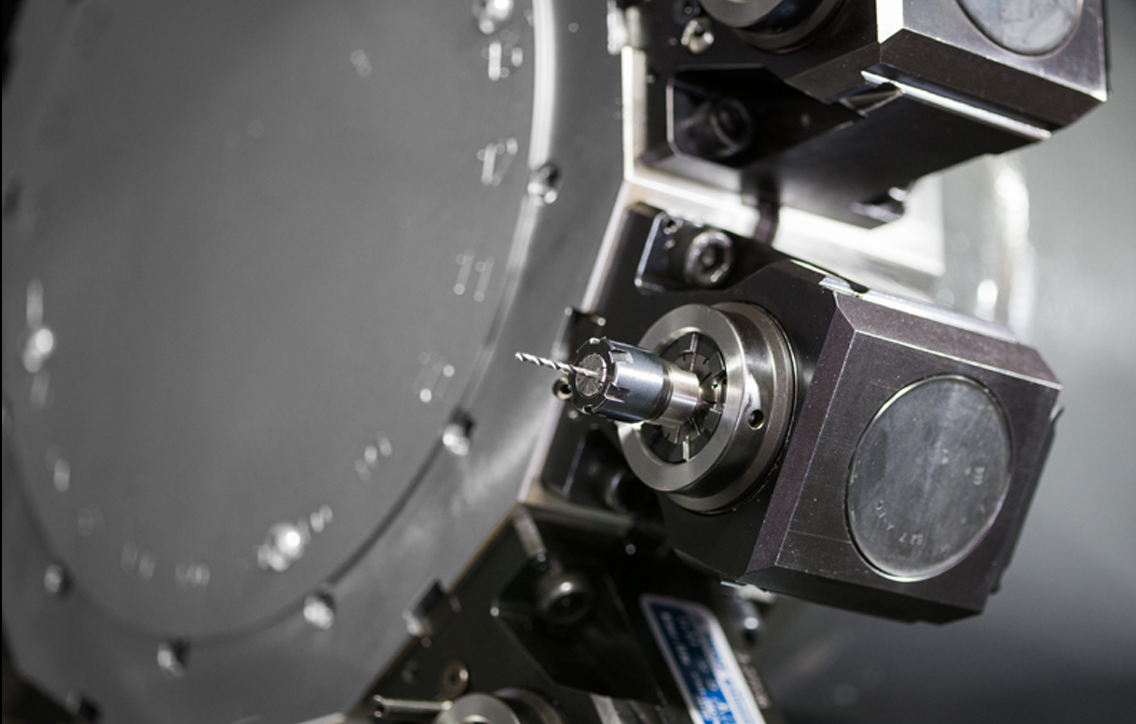

Fabrication

Fabrication services covers a multitude of products, particularly those too large to be moulded. From hand-made bellows and sleeves and rubber lined pipes to cut gaskets, washers and rubber sheeting.

Casting discs

We manufacture our own range of rubber and silicone casting discs for centrifugal casting.

We are happy to recommend J Coker Ltd for all our tool making services.

Russell Mewett, Director, Mewett Polyurethane

Coker’s always do more than is necessary, they are a pleasure to work with.

Brent Hallo, CEO Fitness Professionals.

Coker’s are an absolute pleasure to work alongside, we would be simply lost without them.