1952 - 2024 and beyond....

Our history

J Coker Ltd’s heritage dates back to 1952 when Mr Thomas Coker senior established a rubber and metal casting company in the railway arches of Bermondsey, South London.

Our story

By the early 1980’s Joesph Coker, son of Tom, relocated the rubber moulding business to its current location in Faversham Kent. From this time on, Cokers established themselves as a supplier to the rail and aviation industry, forging a close working relationship with LPA Industries (now LPA Connection Systems) which continues to this day.

Joe was key in developing a range of rubber casting discs to supply to jewellery and model-craft industries, establishing Cokers as one of the leading suppliers of organic rubber discs. This would later be expanded to include silicone grades.

Nestled down on Faversham Creek, the company continued to innovate and expand.

Joe’s son Andrew, a qualified tool maker, joined the company in 2000, sadly after Joe’s passing. Andrew set up a dedicated on-site Tool Room to expand our services and enable us to provide cost effective and speedy tool making services. The tool room now has over 5 HAAS CNC tool room mills and 2 CNC lathes.

Investing in reverse engineering technology, the tool room is accessible as possible to all customers, whether they have a CAD drawing or simply just an old product that needs to be replicated.

In 2000, Maria Baxter, Andrew’s sister, also joined the company. Maria has a background in Business and Marketing, graduating from Sheffield Hallam University in 1994 with a BA Hons Degree in Business Studies. Maria is the first contact in the office for sales and purchasing enquiries and customer support.

Since 2000 Andrew and Maria have invested heavily in new technology to improve efficiency and quality across the company. Coker’s now has a full range of Panstone and Tung Yu automatic moulding presses for precision moulding.

Our in-house Mill Room continues to formulate high quality casting discs. It also helps provide a total rubber solution - feeding compound into the moulding presses in a cost effective and timely fashion.

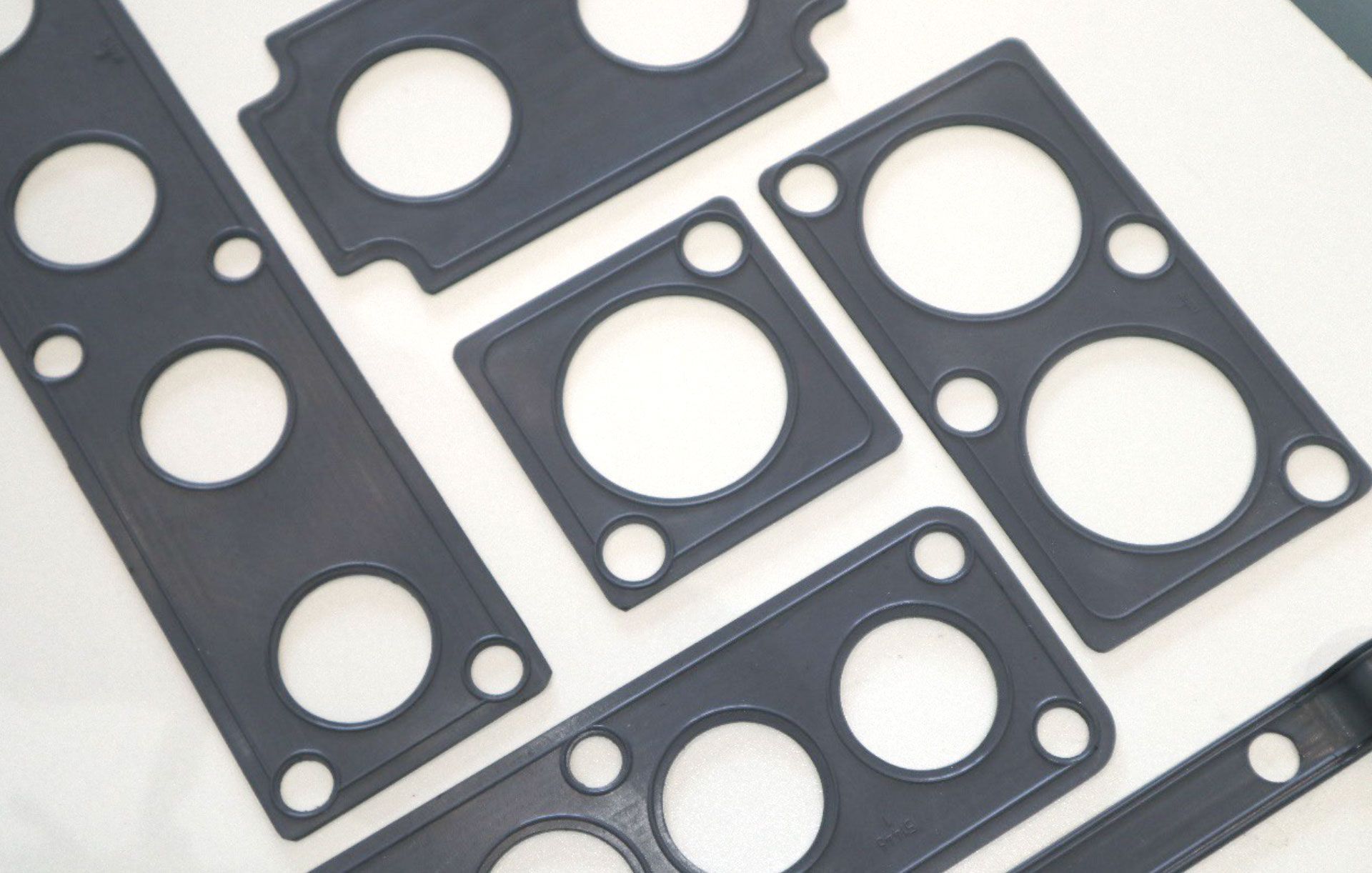

In 2015, Mr Chris King, formerly of J W Challis, joined Cokers to set up a new fabrication department. Chris has overseen the development of this expanding our services to cut gaskets, sheeting and extrusion.

Since its inception in 1952 Coker’s remains a family run professional business with its customers satisfaction central to its values.

INVESTMENT

Investment in our custom-built suite of Panstone automated moulding presses – the best presses in design, performance and technology for the rubber industry.

COKERS ATTENDANCE

At Southern Manufacturing UK