We are your rubber solutions partner for the scale model industry.

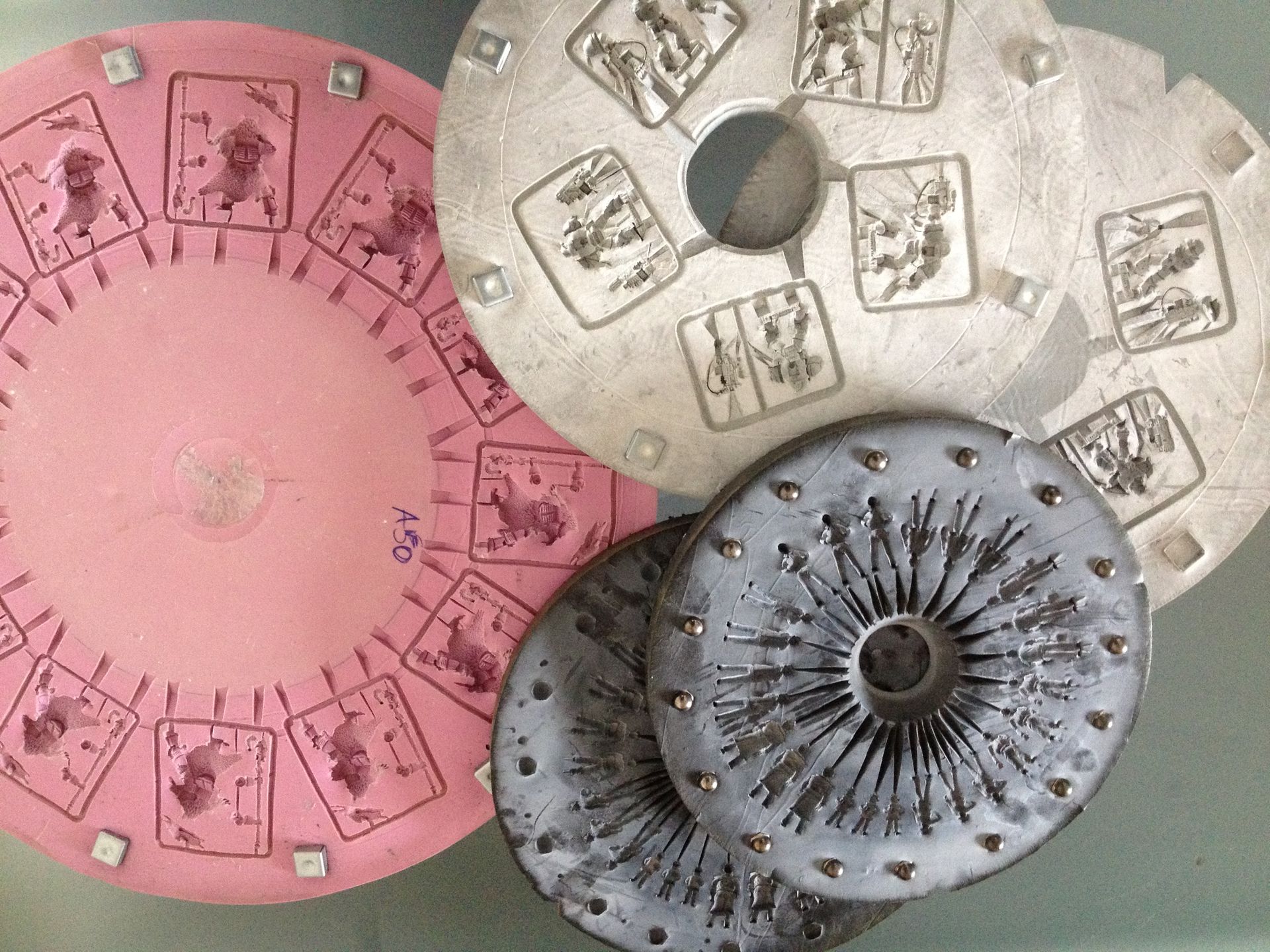

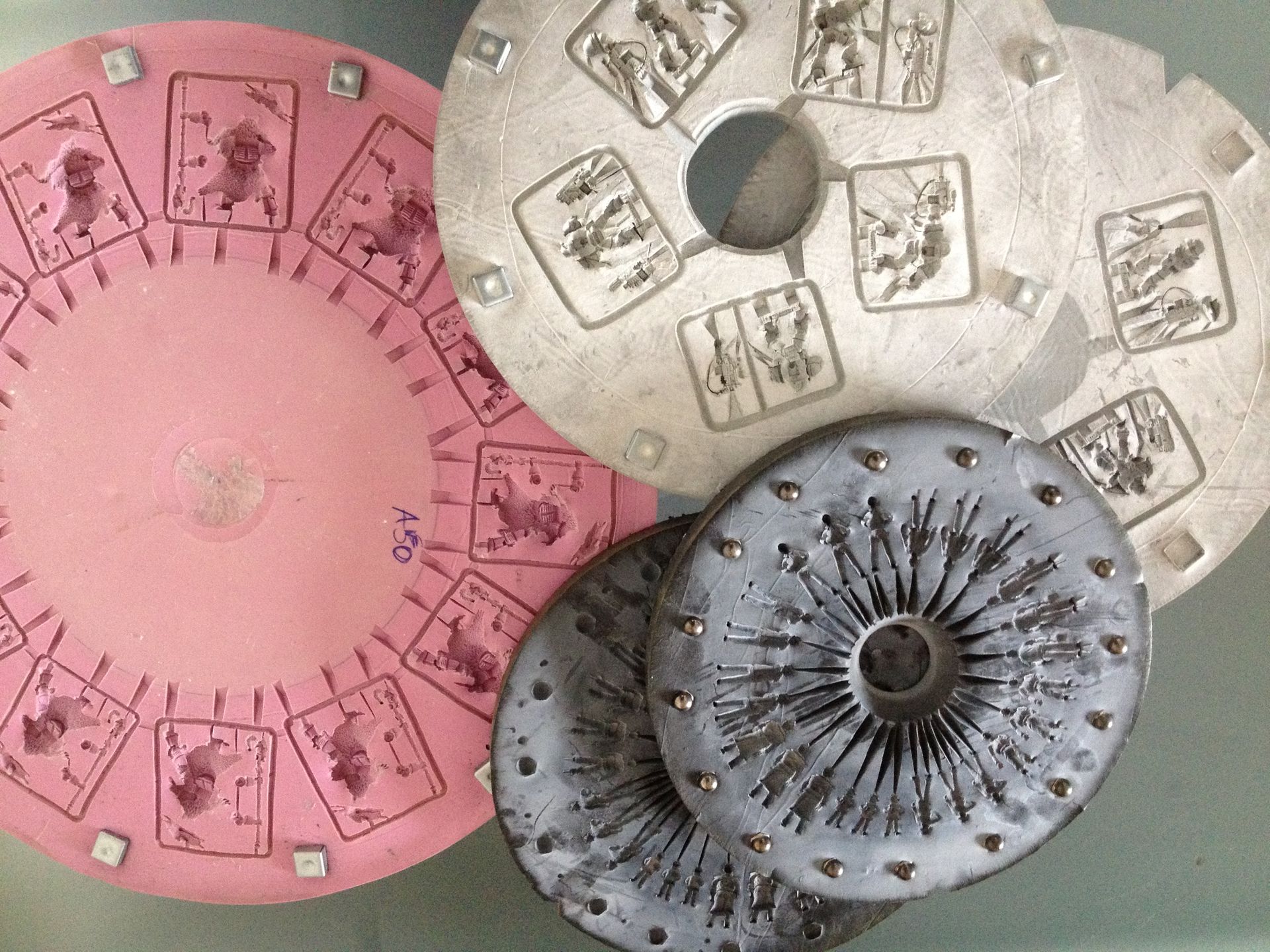

Centrifugal casting, also known as spin casting and white metal casting, uses centrifugal force to produce castings from rubber or silicone moulds.

Used by the giftware and model industries, a wide range of items can be made in this way, from scale model figures, gaming miniatures, fantasy figures to trinkets, jewellery, badges, pins and much more.

Cokers have been supplying our own formulations of casting discs since our establishment in 1952. These include traditional black organic rubber discs alongside a range of silicone formulations.

All formulations are mixed to order on site ensuring ideal usage and maximum shelf life.

Formulations

Black Organic Discs – are a traditional black rubber formation. Each disc is supplied with thin laminations on each side to enable the mould maker to cut their designs. Black discs typically come in different grades defined by their hardness once vulcanised.

Black organic discs are generally cheaper than their silicone alternative. In this way they can be more cost effective, especially for production moulds.

Silicone Discs – are supplied as a putty like mould and are easier to use, especially for beginners. We offer 3 main types of silicone moulds.

Low temperature formulations ideal for delicate masters including resin and putty but also suitable for metal. The formulations have a low vulcanisation point of 80-90 DegC so are excellent at protecting the masters.

General purpose formulations vulcanise at 150 DegC so if you are also using black organic discs there is no need to change the vulcaniser pressure or heat settings. Suitable for pewter.

High heat silicone formulations developed to withstand higher pouring temperatures of zinc and resin and will last longer in spinning than a standard disc can. These also come with a low temperature cure system.

Size and Availability

Discs are supplied in approximately 25mm (1” thickness) pairs. Each pair is supplied in 2 halves of 12.75mm (0.5”) interleaved with polythene.

Standard organic discs are made up of 6 laminations per side which can be peeled away or built up.

Silicone discs are a solid putty like material. The standard size is the same as for the organic discs above. Special ¼ laminations are available in all sizes to help you build up the discs.

Standard sizes include: 6”; 9”; 10”, 11”, 12”, 15”, 16”,

18” and 20”.

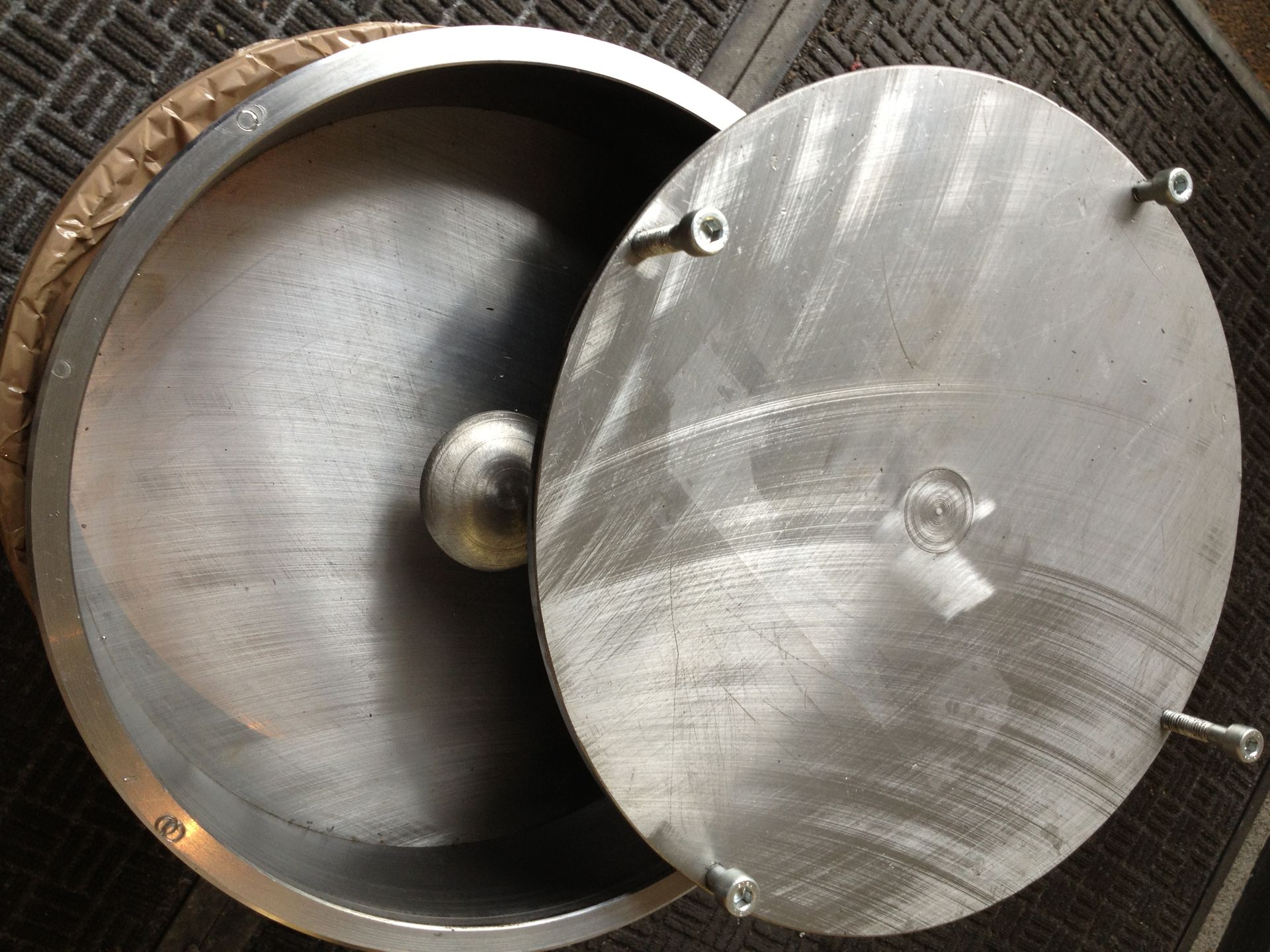

Mould cans

We supply made to measure mould cans. The cans come complete with mushroom and screws. The standard mould can is suitable for a 1” thickness disc. Deeper cans to take 1 ½” or 2” discs are also available.

Hours

8-5pm

Mon - Fri

(open until 1pm on Friday)

Service area

Worldwide

Contact our casting disc specialist

01795 535008

info@j-coker.co.uk

MODEL MAKING: CASE STUDY

Pendraken Miniatures was formed in 1992 by Dave and Lynne Pengilley, focussing on 10mm scale miniatures. Their range now extends to all scales, including 15mm and 28mm figures across a full spectrum of genres: from the dark ages and middle ages; to pre and post wars; and fantasy and sci-fi.

"We've been using Coker for two decades now and both the products and service have always been fantastic. The staff are friendly and help is always available for any technical queries you might have. We'll be continuing to use them for the next two decades hopefully!"

Leon Pengilley, Pendraken Miniatures

Our methods

Tool moulding

The first stage in the design and development process. J Coker’s on-site tool room is headed up by Andrew Coker, a highly experienced tool maker.

Fabrication

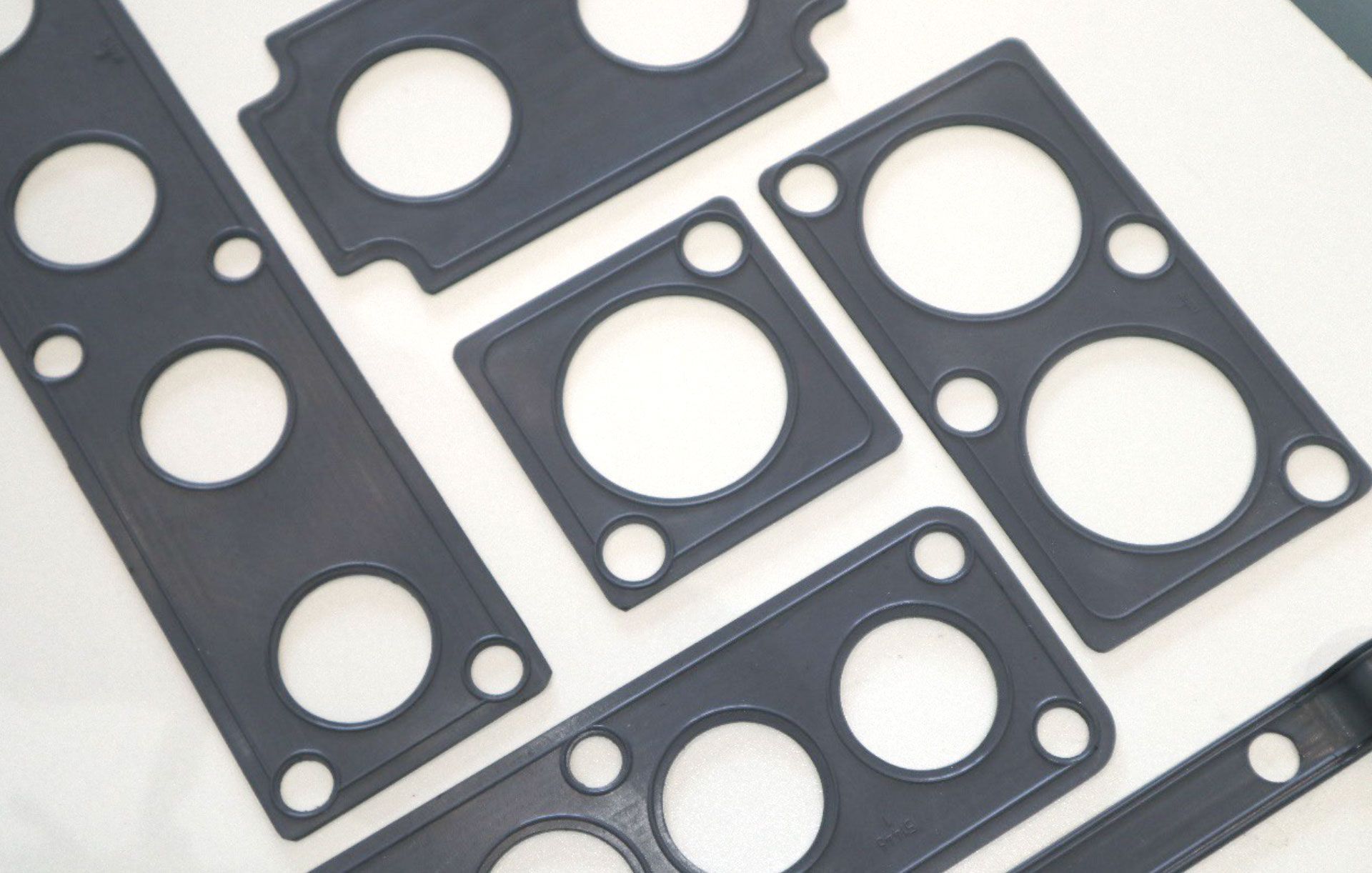

Fabrication services covers a multitude of products, particularly those too large to be moulded. From hand-made bellows and sleeves and rubber lined pipes to cut gaskets, washers and rubber sheeting.

Casting discs

We manufacture our own range of rubber and silicone casting discs for centrifugal casting.

We highly recommend J Coker Ltd

Neil Sharpe, Purchasing Manager, LPA Connection Systems

Cokers really helped us out with our projects. Speaking to their design team allowed us to more closely understand the processes they use, which meant we could adjust our design to reduce tool making time and improve productivity. We have been very impressed.

Joe Gibbons, CAD Engineer, DJH Engineering.

We've been using Coker for two decades now and both the products and service have always been fantastic. The staff are friendly and help is always available for any technical queries you might have.